Infrared proximity switches work by sending out beams of infrared invisible light. With the aid of specific techniques like magnetic, electric, or optical methods, an assertation of the proximity of an object can be achieved. Therefore, these switches can determine whether an object is present. These switches have numerous security-related applications and can be used to measure a motor’s rotational speed. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At Telamco, Inc., we specialize in the design and manufacturing of high-quality membrane switches, providing our clients with robust solutions that meet their diverse needs across a variety of industries. Our products are crafted with precision to deliver durability, reliability, and exceptional performance in environments where control and durability are paramount.

At Cole Graphic Solutions, we specialize in providing high-quality membrane switches designed to meet the unique needs of a variety of industries. With a commitment to excellence, we offer custom solutions that are built to deliver exceptional performance, durability, and precision.

More Proximity Switch Manufacturers

Proximity Switches: The Complete Guide to Types, Applications, Selection & Industry Benefits

Proximity switches, also known as proximity sensors, are electronic devices designed to detect the presence of nearby objects without direct physical contact. Using the aid of a magnetic or electromagnetic field, these switches can recognize the approach of a metallic device component or other target materials. Unlike traditional mechanical switches, proximity switches offer contactless detection, leading to higher durability, reliability, and versatility in industrial automation, robotics, manufacturing, automotive, and home automation systems.

Normal proximity switches employ a permanent magnet to generate a sealed switch mechanism when a mechanical component of an object approaches. Some advanced proximity sensors can function as metallic detectors; these are referred to as complex proximity switches. Complex proximity switches work by electrically energizing a coil of wire, with the current's strength electronically tracked. If a metallic object approaches the coil, the monitoring section will trip, activating or deactivating the connected system.

What is a Proximity Switch and How Does It Work?

A proximity switch is a type of sensor that detects the presence or absence of an object in its vicinity without any physical contact. It operates by emitting an electromagnetic field or a beam of electromagnetic radiation (such as infrared), and monitoring changes in the field or return signal. When a target object enters this field, the sensor's circuitry responds by sending an electrical signal that can be used to control machinery, trigger alarms, or log data.

Key benefits of proximity switches include their long operational life, high-speed sensing capability, and resistance to environmental contaminants like dust, oil, and water. This makes them ideal for harsh industrial environments, as well as applications requiring frequent or rapid switching.

Types of Proximity Switches

The different types of proximity sensors include:

Inductive Proximity Switch

Inductive proximity switches are widely used non-contact sensors capable of detecting metallic objects without physical contact. They are highly favored in the automation industry for tasks demanding rapid and accurate detection. Powered by an oscillator, the coil in an inductive switch generates an alternating electromagnetic field. When a metallic object enters this active region, eddy currents are induced in the object, diminishing the field's strength. This reduction is detected by the switch, which then toggles its output.

Common use cases for inductive proximity switches:

- Detecting the position of metal parts in assembly lines

- Monitoring the rotational speed of gears and shafts

- Counting and sorting metal components (e.g., screws, bolts)

- Ensuring machinery safety by identifying open/closed guards or covers

Advantages of Inductive Proximity Switches

- High switching speed and accuracy

- Non-contact operation reduces mechanical wear

- Resistant to dirt, oil, and water

- Ideal for harsh industrial environments

Capacitive Proximity Switch

Capacitive proximity switches are versatile sensors capable of detecting both conductive and non-conductive materials. They operate by monitoring changes in capacitance between two electrodes. When an object—whether solid, powdery, or liquid—enters the field, the capacitance shifts, prompting the switch to activate. Unlike inductive sensors, capacitive switches can detect plastics, glass, wood, paper, ceramics, water, oil, and more, in addition to metals.

Applications and Use Cases for Capacitive Proximity Switches

- Level detection in tanks for liquids or granular materials

- Presence detection in packaging lines (detecting plastic, glass bottles, or cartons)

- Position sensing in conveyor systems

- Object counting and sorting of diverse materials

- Detecting build-up of product on machinery

Advantages

- Detects a wide variety of materials (metallic and non-metallic)

- Non-contact, wear-free operation

- Can sense through thin non-metallic containers or walls

Ultrasonic Proximity Switch

Ultrasonic proximity switches use high-frequency sound waves to detect objects and measure distances. These sensors emit ultrasonic pulses and listen for their echo, calculating the distance based on the time delay. Ultrasonic switches are invaluable in applications where the material or color of the object may interfere with other sensor types.

Common Applications

- Level measurement in tanks, silos, and hoppers (liquids and solids)

- Object detection and distance measurement in robotics and AGVs

- Obstacle avoidance in automated guided vehicles

- Presence detection in parking sensors and security systems

- Monitoring fill levels in packaging and bottling lines

Advantages

- Reliable in dusty, humid, or dirty environments

- Not affected by object color, transparency, or surface finish

- Can sense at distances up to 10 meters or more

Optical Switch

Optical proximity switches, also known as photoelectric sensors, use a light source (such as LED or laser) and a photodetector. When the light beam is broken or reflected by an object, the sensor responds by altering its output. These switches are extremely fast and can detect small or transparent objects, making them popular in packaging, sorting, and safety applications.

Optical Switch Use Cases

- Presence detection in automated assembly lines

- Counting and sorting of packages, bottles, or products

- Safety interlocks for machine guarding

- Detection of transparent or colored objects

- Quality control in printing and labeling systems

Advantages

- Highly accurate and fast response

- Can detect small, transparent, or non-metallic objects

- Flexible sensing modes (through-beam, retro-reflective, diffuse)

Key Features to Consider When Selecting Proximity Switches

When evaluating proximity switches or proximity sensors for your application, keep these critical criteria in mind:

- Sensing distance: Ensure the sensor can detect objects at the required range for your process.

- Target material: Match the sensor type (inductive, capacitive, ultrasonic, optical) to the material to be detected.

- Switching frequency: Consider the speed at which the sensor must detect and respond to objects.

- Environmental resistance: Assess the sensor’s ability to function in the presence of dust, moisture, oil, chemicals, or extreme temperatures.

- Output type: Choose between NPN, PNP, relay, analog, or other interfaces to match your system controls.

- Installation requirements: Consider housing size, mounting options, cable versus connector, and protection ratings (IP65, IP67, etc.).

- Certifications and standards: Check for CE, UL, RoHS, and other industry-specific approvals required for your market.

Applications of Proximity Sensors Across Industries

Proximity sensors and switches are essential components in a wide array of industries, providing reliable, maintenance-free detection in harsh and demanding environments. Here are some of the leading application areas:

- Industrial automation: Detecting object presence and position in assembly and production lines, robotic arms, and material handling systems.

- Automotive industry: Used in parking sensors, seat occupancy detection, vehicle proximity alerts, and anti-collision systems.

- Home automation: Triggering lighting, alarms, or smart home devices when someone enters a room or approaches an entrance.

- Packaging and processing: Counting and sorting products, detecting jams, and level monitoring in filling machines.

- Consumer electronics: Used in touchless controls for mobile phones, tablets, and appliances.

- Medical devices: Ensuring contactless operation in diagnostic equipment and safety interlocks on medical machines.

- Security systems: Intrusion detection, door and window status monitoring, and access control.

- Machine tool monitoring: Measuring the speed and direction of electric motors, confirming tool presence or breakage.

- Conveyor systems: Object counting, spacing, and jam detection for optimized throughput.

Want to know which proximity sensor suits your industry?

Explore our detailed industry guide or contact our technical experts for tailored recommendations based on your environment, target materials, and operational requirements.

Benefits of Using Proximity Switches in Modern Systems

- Non-contact operation: Eliminates mechanical wear, reducing maintenance and improving reliability.

- High-speed switching: Capable of detecting fast-moving objects and supporting rapid production cycles.

- Durability: Resistant to contaminants such as dust, oil, water, and chemicals.

- Flexibility: Available in multiple sensing technologies to suit various materials and operational environments.

- Compact design: Easily integrated into modern automated systems and tight spaces.

- Safety: Reduces risk of operator injury by enabling automated machine interlocks and emergency stops.

- Energy savings: Enables intelligent system control, reducing unnecessary operation and power consumption.

Common Buyer Questions About Proximity Switches

Looking to purchase proximity switches for your next project? Consider these frequent questions from buyers and engineers:

- What type of proximity switch is best for detecting plastic or liquid containers?

- How do I determine the correct sensing range for my application?

- Are there explosion-proof or intrinsically safe proximity sensors for hazardous areas?

- Can proximity switches be used outdoors or in extreme temperatures?

- What output types are compatible with PLCs or industrial controllers?

- How do I install and wire different proximity switch types?

- What certifications should I look for when sourcing proximity switches for regulated industries?

Still have questions? Reach out to our support team for technical assistance or product selection guidance.

Choosing the Correct Proximity Switches Manufacturer

Selecting the right proximity switches supplier or manufacturer is crucial for ensuring quality, reliability, and support for your automation or sensing needs. To make sure you have the most productive outcome when purchasing proximity switches, it is important to compare at least 5 or 6 companies using our curated list of proximity switches manufacturers. Each manufacturer profile highlights their experience, certifications, industry focus, and available product lines. Utilize business profile pages to review their capabilities, and use the integrated contact forms to request quotes or technical information directly.

- Review each company's specialty using our proprietary website previewer—see at a glance their core products, target industries, and value-added services.

- Use our simple RFQ (Request for Quote) form to contact multiple proximity switches businesses simultaneously, saving research time and ensuring competitive pricing.

- Check for after-sales support, warranty terms, and available documentation such as datasheets, installation guides, and compliance certificates.

- Look for customer testimonials and case studies demonstrating successful proximity switch implementations in your field.

- Evaluate lead times, minimum order quantities, and customization options to ensure the supplier can meet your project requirements.

How to Compare Proximity Switches Manufacturers

- What industries do they serve (industrial automation, automotive, food processing, etc.)?

- Do they offer specialized or custom proximity sensors for unique applications?

- Are their products certified to international standards (CE, UL, ISO, etc.)?

- What technical support, training, or integration services are offered?

- What is their reputation for quality and on-time delivery?

By systematically comparing suppliers, you can confidently choose a proximity switches manufacturer that aligns with your technical, commercial, and operational needs.

Proximity Switch Installation and Maintenance Best Practices

- Follow manufacturer guidelines for mounting position and distance to avoid false triggering or missed detection.

- Shield the sensor from electromagnetic interference (EMI) where applicable, especially in environments with heavy machinery.

- Regularly inspect wiring and connectors for signs of wear, corrosion, or damage.

- Test proximity switches as part of preventative maintenance to ensure proper operation.

- Keep sensors clean from accumulated dust, oil, or debris, especially for optical and capacitive types.

Need help with installation or troubleshooting?

Browse our comprehensive proximity switch installation guide or submit a support request for personalized advice from certified technicians.

Frequently Asked Questions (FAQ) About Proximity Switches

What is the difference between a proximity switch and a proximity sensor?

While the terms are sometimes used interchangeably, a proximity sensor generally refers to the sensing element that detects objects, while a proximity switch is the device that outputs a switching signal when detection occurs. Most modern proximity switches integrate both sensing and switching functions for seamless operation.

Which proximity switch is best for non-metallic object detection?

For detecting non-metallic objects such as plastic, glass, wood, or liquids, capacitive proximity switches, ultrasonic sensors, or optical switches are typically recommended, depending on application specifics like range, environment, and object properties.

Can I use proximity switches in outdoor or washdown environments?

Yes, many proximity switches are available with high protection ratings (e.g., IP65, IP67, or even IP69K) and can withstand outdoor conditions, high-pressure washdowns, and exposure to chemicals. Always verify the sensor’s enclosure rating and material compatibility for your intended environment.

How do I wire a proximity switch to a PLC or controller?

Most proximity switches offer either NPN or PNP transistor outputs, or relay/analog outputs for integration with PLCs and automation controllers. Wiring diagrams are typically provided in the product datasheet. Ensure voltage compatibility and proper input configuration on your controller.

Ready to Source Proximity Switches or Need Expert Advice?

- Request a quote from leading proximity switch manufacturers today

- Download our comprehensive proximity sensor buyer’s guide

- Contact technical support for application-specific recommendations

Maximize efficiency, safety, and automation in your facility with the right proximity switches—explore your options, compare suppliers, and make an informed purchase decision today.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

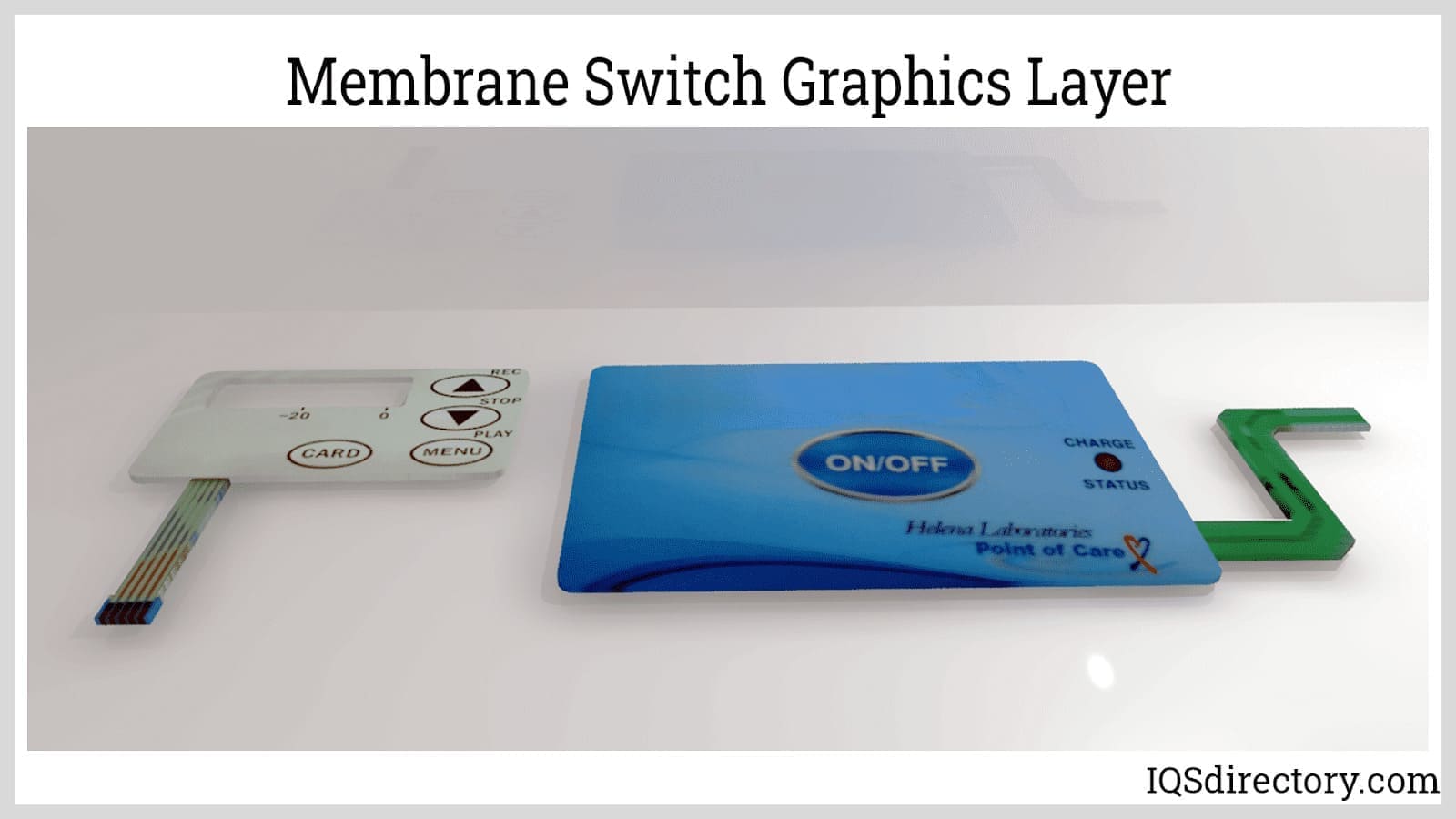

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services