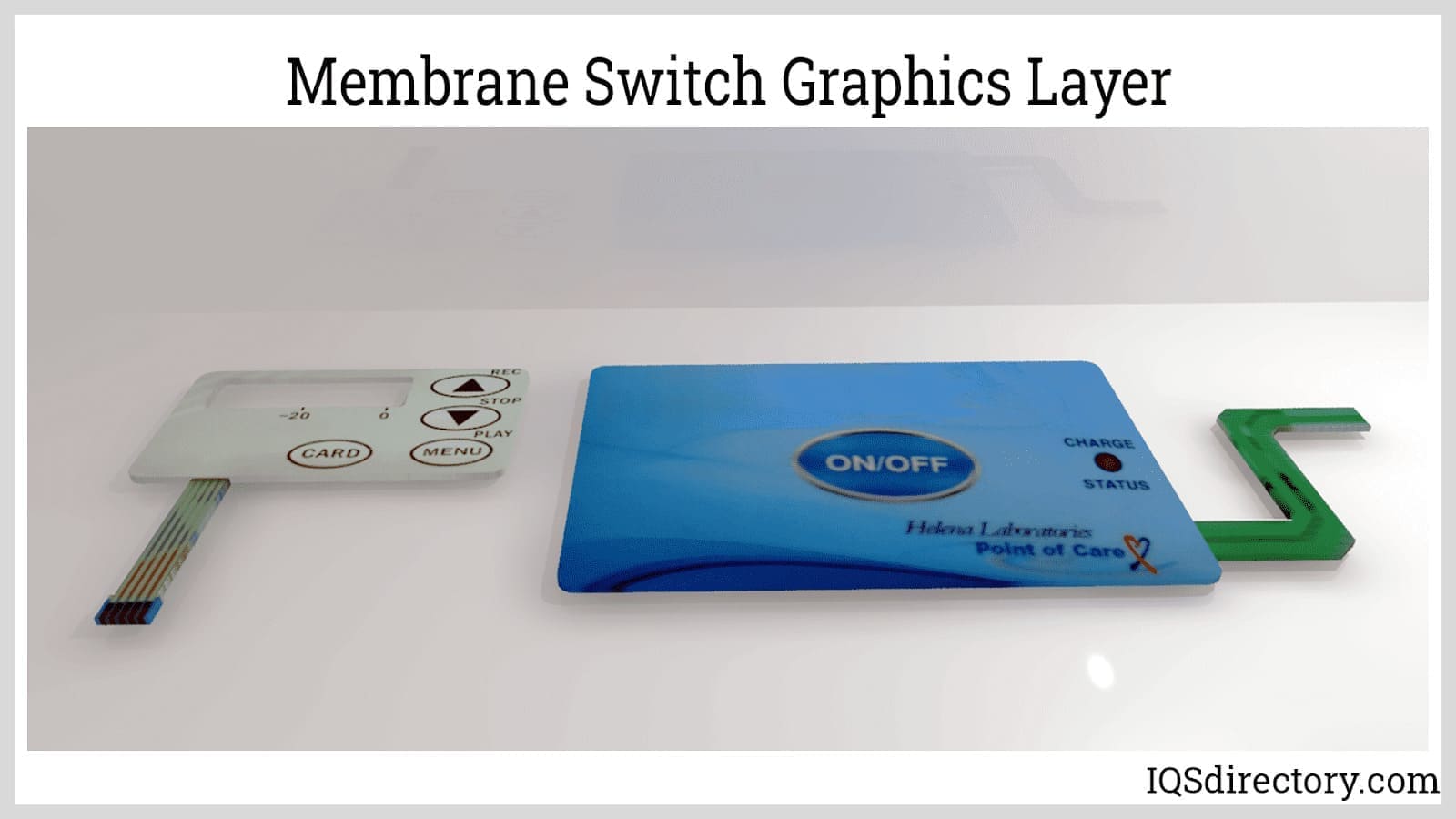

A mechanical switch is generally made of plastic parts and copper. A membrane switch, on the other hand, is a circuit printed on polyethylene terephthalate (PET) or indium tin oxide (ITO). The ink with which a membrane switch is printed is usually copper, silver or graphite, all conductive materials. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

ECI Technologies is a leading designer and manufacturer of innovative membrane switches, graphic overlays and electronic interfaces. We can produce tactile and non-tactile switches and keypads, as well as add features such as backlighting and environmental protection. We also offer quick-turn prototype design and production. Since 1991, we have been serving industries such as industrial, medical, ...

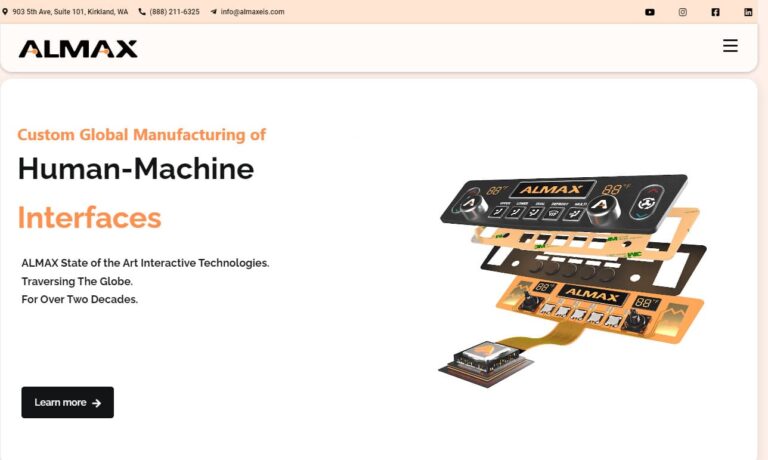

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At New England Keyboard, we manufacture tactile switches and a variety of other products to help our customers in industries and companies around the world. We operate with integrity and the latest technologies so that our customers can succeed at all times. We believe in creating products that we can be proud of, and that you can too. Contact New England Keyboard today to learn more about us!

Tapecon works with product teams to improve market competitiveness through outsourced manufacturing solutions with expertise in specialized printing and converting, printed flexible electronics, and contract manufacturing of disposable devices for medical and industrial markets. Established in 1919, Tapecon is a 5 generation, family owned contract manufacturer based in Buffalo, New York.

More Membrane Switch Panel Manufacturers

Many membrane switches require some sort of support so that, for example, a user can push an activation switch successfully. These supports are called membrane switch panels. In addition to supporting switching functions, membrane switch panels also enhance the final product with a tailored decorative appearance. Switch panels may be on the front, back or both.

Membrane switch back panels can be produced using many materials, the most common being aluminum. Aluminum panels can be bare, iridited, alodined, painted or anodized. Other types of membrane switch back panels include plastic injected molded cases/front covers, other metal panels, circuit board materials, stainless steel, acrylic, polycarbonate and ABS.

Plastic injected molded case panels consist of a molded cavity that receives the membrane switch, parting lines, bosses and injector pin marks. The molded cavity allows the membrane switch to be flush with the case surface. Manufacturers must take care to keep everything else away from the switch button locations, to ensure a lack of switch actuation issues. These membrane switch panels are popular in the medical industry.

Typically made of aluminum or steel, metal back panels are popular in industrial applications. They are commonly coated with a protective finish to prevent corrosion. A very common metal and finish combination is black anodized aluminum, as it conforms to any shape, size or thickness that the membrane switch requires.

Printed circuit boards (PCBs) may be used as panels when they lack circuitry. They allow for similar hardware to be installed as metal panels, which allows the panel to be lighter and non-conducive. This type of membrane switch panel is most commonly used in portable equipment that needs to be lighter, such as phone systems and radio controllers.

Membrane switch panels have applications in many industries, including military, defense, aerospace, audio, medical, food and beverage, time management and home security. More specifically, they may be used in dash boards, control cases, GPS, ATMs, self-checkout machines, vending machines, kiosks and more. Membrane switch panels may be designed using a number of custom design options, such as associated electronic assemblies, simple or two-stage backlighting, EMC protection, sealing, reinforced sealing and custom support plating.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services