Amidst the waves of technology that continually wash over the modern world, keyboards still stand the test of time. They do not, however, remain unchanged. The standard keyboard now stands alongside several types, such as multifunctional, handheld and flexible keyboards, made from different materials. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

At ECI, our silicone keyboards can be manufactured using both compression and injection molding capabilities. We can make the keypads and the individual keys itself in virtually any color, shape, or size. Contact us today with your specifications, and we will design a rubber keyboard tailor-made to your needs. Because the keypads are molded, their designs can vary from super simple to...

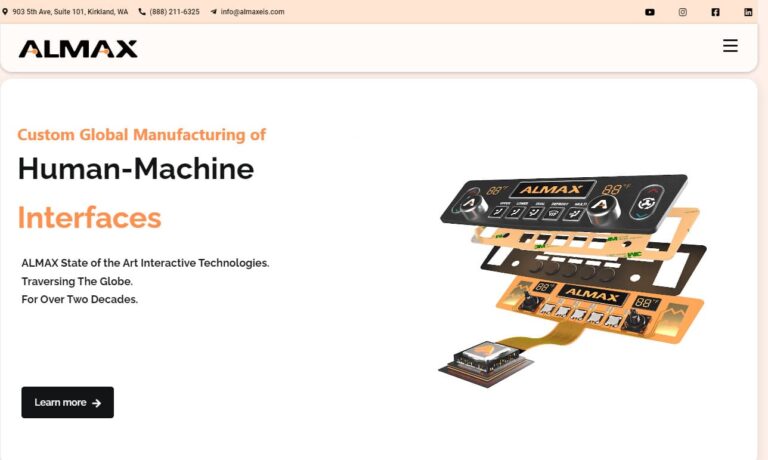

With over 30 years of experience, ALMAX is a leading manufacturer of membrane switch assemblies, printed/flexible electronics, and interactive technologies. Our engineering and manufacturing capabilities are implemented and trusted around the globe, and we're proud to offer our clients a complete range of services that meet the highest standards of quality and reliability.

Established in 1982, we at CSI Keyboards, Inc. have been at the forefront of the industry, dedicated to crafting exceptional membrane keyboards, membrane switches, and keypads. Since our journey began, we have honed our expertise to become a leading force in the field. Our skilled team of professionals is passionate about pushing the boundaries of membrane switch technology, consistently...

At New England Keyboard, we manufacture tactile switches and a variety of other products to help our customers in industries and companies around the world. We operate with integrity and the latest technologies so that our customers can succeed at all times. We believe in creating products that we can be proud of, and that you can too. Contact New England Keyboard today to learn more about us!

Tapecon works with product teams to improve market competitiveness through outsourced manufacturing solutions with expertise in specialized printing and converting, printed flexible electronics, and contract manufacturing of disposable devices for medical and industrial markets. Established in 1919, Tapecon is a 5 generation, family owned contract manufacturer based in Buffalo, New York.

More Silicone Keyboard Manufacturers

One of these keyboard types is the silicone keyboard. Along with the silicone keyboard stands the silicone keypad, which uses similar technology. Keyboards and keypads made from silicone are common for a number of reasons. Firstly, silicone is considered to be an abundant resource, and as a result, products made with it can be cheaply produced. Secondly, a silicone keyboard can be quite durable, in some ways even more durable than a standard keyboard. Additionally, the silicone keyboard skin can protect the keyboard from many different substances.

One type of keyboard that is almost universally made from silicone is the flexible keyboard. Its silicone makeup allows it such flexibility that it can be rolled up or folded, though it must be on a hard surface to work. The silicone is also liquid and dust proof.

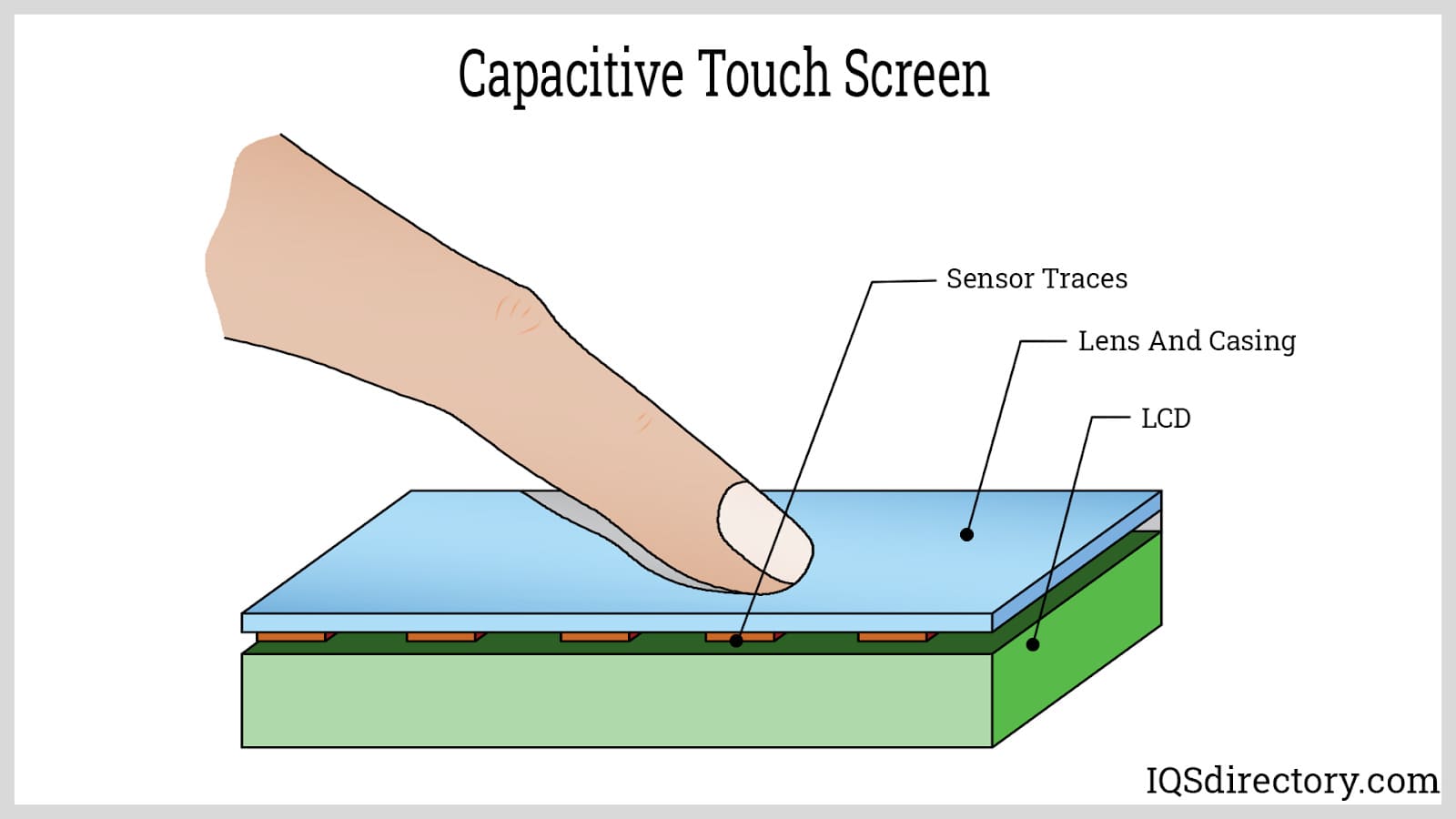

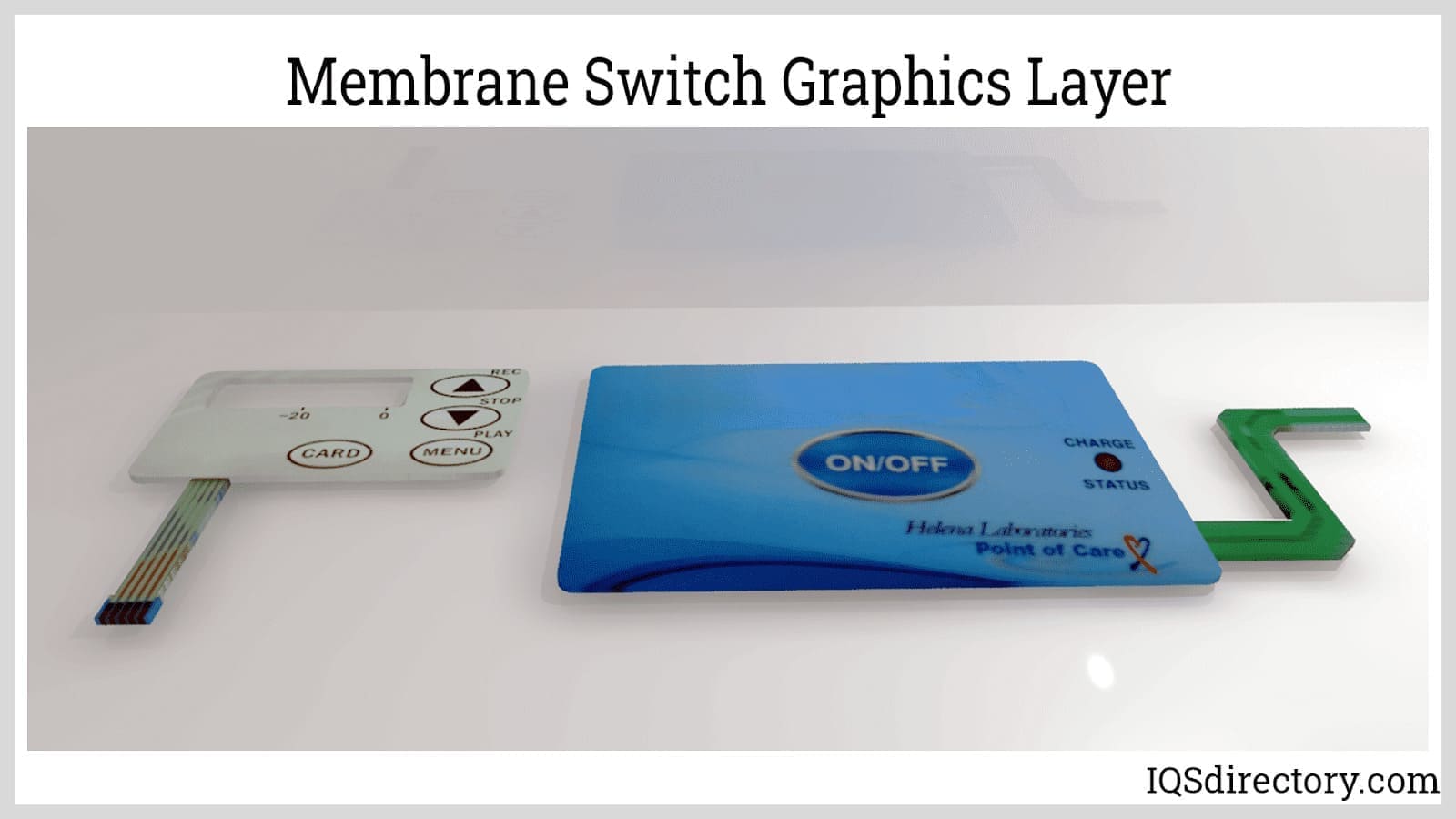

Silicone keypads use the compression molding properties of silicone rubber to create angled webbing around a switch center, which, when pushed down, uniformly deforms to produce a tactile response. When the pressure is released, the switch returns to its neutral position with positive feedback.

Silicone keypads are not generally used with computers per se, but rather have applications in TV remote controls, video and HIFI units, mobile handsets, low current switching in automobiles, electronic games and toys, and industrial control equipment. Such equipment is used in the marine, medical, and military industries, and is sealed to comply with specific industry standards for protection against elements like dust and liquids.

A silicone keyboard or keypad can be customized to create several different surface effects. For example, a keyboard or keypad can take one, multiple or flowing colors through the addition of pigment into the natural silicone. Individual keys can also be illuminated by SMT LEDs that are placed on circuit boards after laser etching.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services